Aluminium Honeycomb Panel: A material for Special Design that defines identity

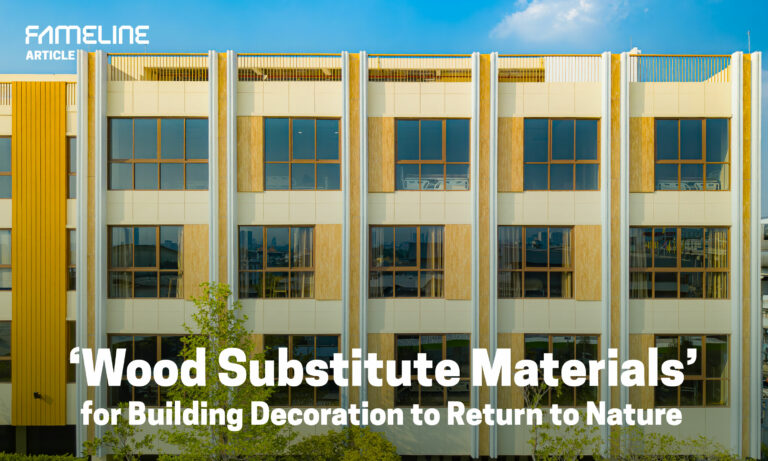

In the changing world of modern architecture, there is a focus on integrating technology and innovation with unique shapes, adapting to society, culture, climate conditions, pollution, resources, labor, and construction methods. This is the challenge for architects to find new alternatives that make designs uniquely distinctive, following values that require more individuality and privacy, often driven by the project owners themselves. Thus, the choice of construction materials must be able to support special (Special Design) or customized (Customized Design) shapes, surpassing the limitations of design and enhancing imagination.

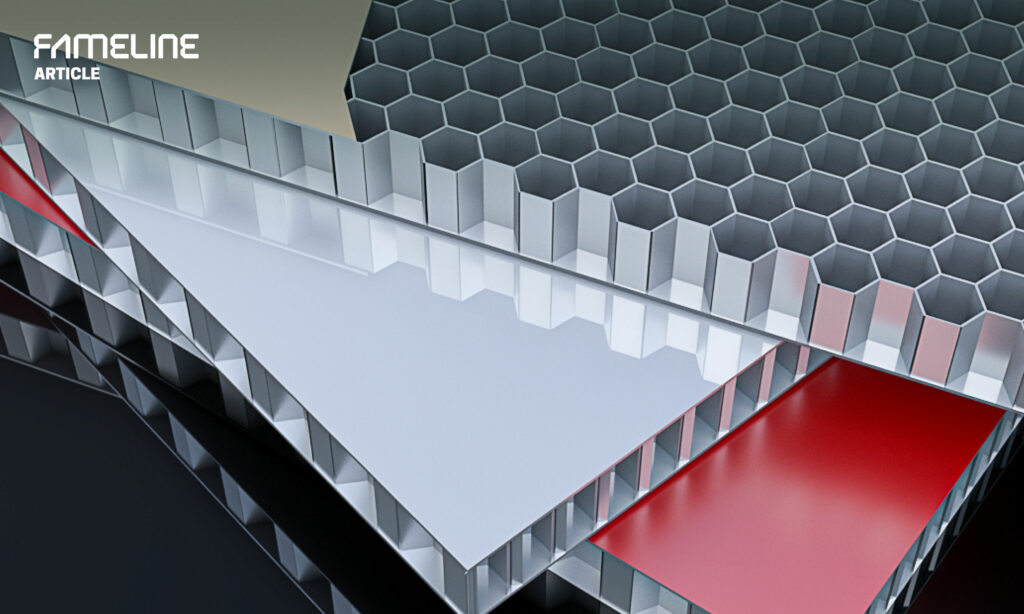

Materials capable of meeting both of the mentioned characteristics must be of special quality and offer greater flexibility in application. For instance, the Aluminium Honeycomb Panel from FAMELINE represents an innovation within the Aluminum Composite Panel category. It is gaining popularity and increasingly used internationally, stemming from the prototype use of aluminum materials in other industries such as aerospace and automotive, to becoming a construction material. This is due to the reinforcement of aluminum as a core in a honeycomb (Honeycomb) structure.

Lightweight and Exceptionally Safe

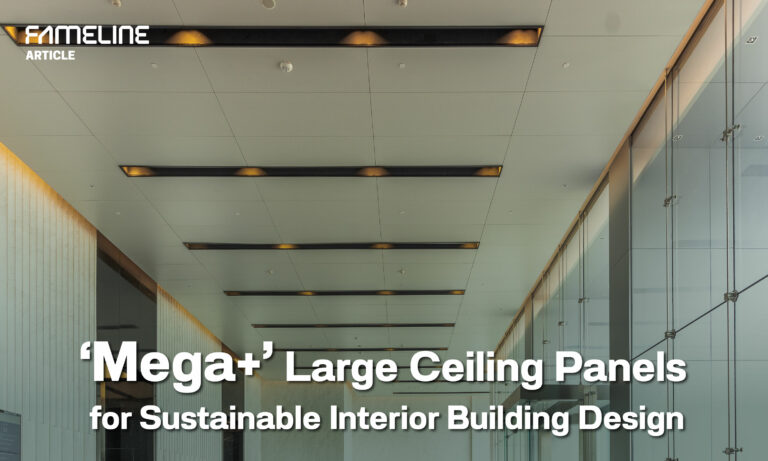

The honeycomb structure is inspired by the natural hexagonal honeycomb, a geometric shape that is strong due to the even distribution of weight in multiple directions. This allows it to resist bending, torsion, and compression, absorb energy, and distribute impacts effectively. The natural flexibility of the honeycomb structure enables easy shaping and form retention, leading to long-term durability. This results in a uniformly strong structure across the entire panel, compared to its reduced weight, making it ideal for designing in large aluminum panel formats. This helps minimize the seams between panels, offering an expansive view of the space, suitable for the proportions of especially large buildings. It can be used for covering building exteriors (Façade), wide fin façades that can extend up to 6 meters (or more, in special designs), or chosen as ceiling finishes for large building lobbies.

Compared to similar construction materials (depending on thickness, density, type, and mixed materials), concrete weighs about 240 kg per square meter, steel about 78.5 kg per square meter, and wood about 12.5 kg per square meter. In contrast, Aluminium Honeycomb Panels (AHP) weigh about 4-5 kg per square meter. Despite their lightweight, they are strong and used in the aviation and space industry, automotive, and marine industries, requiring high safety standards. This aligns with the design direction for high-rise buildings and large public buildings, considering the large number of daily users.

AHP from FAMELINE meets the European standard EN 13501-1 with a Fire Rating of Class A2, emitting less heat in combustion and extinguishing immediately when the fire source is gone. Commonly, AHP also has an aluminum honeycomb core, a material that is not flammable, making it suitable for construction industries with strict fire safety regulations, including skyscrapers, condos, hotels, airports, train stations, or sports arenas.

Today, buildings wrapped in AHP, trusted by world-renowned architects for their unique design shapes like Beijing Daxing International Airport by Zaha Hadid Architects, demonstrate durability against weather conditions and safety confidence for interior users.

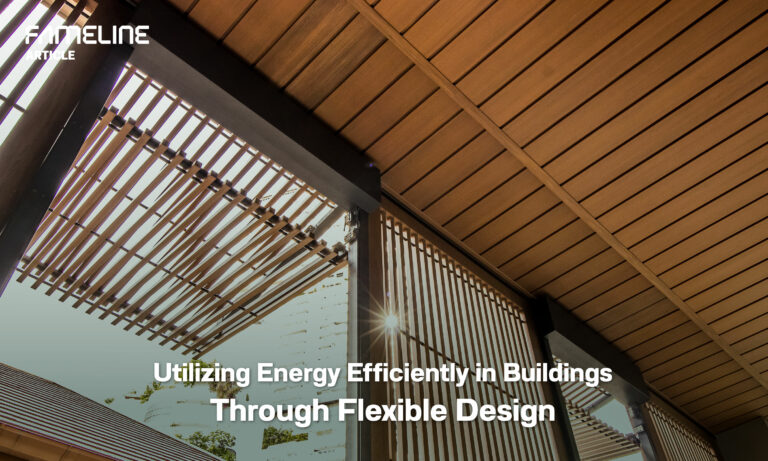

Special Installation Reduces Resources

Unconventional designs sometimes require special time, craftsmanship, and equipment for installation, potentially increasing unnecessary costs and affecting the material’s lifespan due to non-standard installation. However, AHP from FAMELINE, available in thicknesses from 6-50 mm and using Series 3000 aluminum grade sheets that can directly bear weight and withstand wind and impact forces, allows for use in complex design concepts. Whether in shape, size, color, or installation, it can be used in straight panels or curved as desired without losing shape, like Mega Panel Cladding, Mirror Aluminium Cladding, Wide Fin Façade, Lightweight geometric Façade Design, or Free-Form Covered Walk Way.

The installation of AHP uses a dry system with steel or aluminum frames, securing the panel with screws at required weight-bearing points. Designed as factory-prepared panels, edges can be sealed, cut, or formed to fit the usage, certified and quality-checked, with every production step occurring in Thailand (Made in Thailand: MiT) by skilled teams and modern machinery, allowing for rapid assembly on site. This promotes the concept of ‘Prefabricated Construction’, making construction work faster and more efficient, meeting tight schedules, reducing material waste and labor costs, and ensuring consistent high-quality production standards.

Sustainability Promoted by Special Materials

The trend towards prefabricated construction also promotes sustainability by reducing material loss, energy use, and environmental impact from on-site construction processes. Choosing aluminum construction materials reduces resources in the production process, being 100% recyclable without radioactive components or evaporation substances. It saves energy through the insulating properties of the honeycomb structure, as the air space between layers acts as an effective barrier against sound transmission, noise absorption, and thermal insulation, maintaining comfortable indoor temperatures, promoting energy savings for buildings, and supporting sustainable construction concepts. This is crucial for modern architectural design.

Summary

Additionally, business growth must be supported by architectural design, with project owners expecting differentiation and market appeal. Sometimes, traditional materials may not meet design requirements, need adaptability. AHP allows architects to meet client demands more effectively, combining new technologies for more diverse shapes, making ‘Special Design’ or ‘Customized Design‘ sought after for fresher concepts and greater identity.

บทความอื่นๆ ที่เกี่ยวข้อง